Smart Key: Can metallic accessoires be ecological and ethical? The - Accessories - Première Vision Paris - Denim Première Vision - Première Vision New York

Unlock the secrets of sustainable materials with our Smart Keys.Take an in-depth look at the questions around eco-design, as we analyse the solutions available to make your materials sourcing even clearer! Today, let’s discover the golden rules of ecological and ethical accessories. They are the detail that makes the difference, that gives the shine to a silhouette. Whether in the form of buttons, clasps, chains or jewellery, metallic accessories emphasise the personality of a product. Responsible production is not limited to the sourcing of leather or fabric, as these days the humblest of components can illustrate the commitment of a label.

Metal matters: behind the scenes of the mining industry

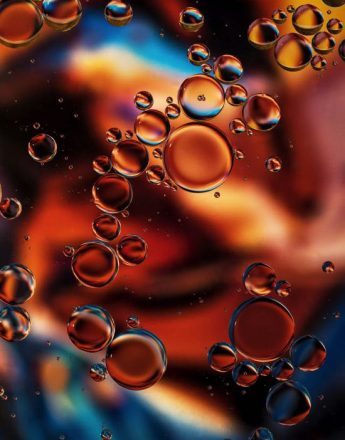

The mining industry is in the spotlight as much for its environmental aspects as for ethical considerations.

To excavate metal ores, intensive chemical and physical operations are necessary. Soil erosion, high energy consumption and pollution of the water table with the toxic runoff are the results of the use of these precious non-renewable resources.

Gold mining and processing requires the use of cyanide, mercury and caustic soda, frequently producing sludge that is either acidic or has high concentrations of dangerous metals.

Many foundries do not have systems for recovering emissions, rigorous filtration systems or reliable protective equipment.

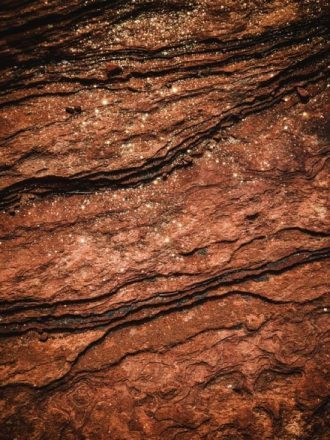

The processing of ores can also release sulphur dioxide, increasing acid rain and air pollution. Those most affected by these harmful substances are miners, foundry workers and the neighbouring populations, with disastrous consequences on health as a result of these processes.

Economic considerations once again take precedence over the enforcement of decent and safe working conditions. Child labour, modern slavery, populations forced off their lands and the collapse of mines remain prevalent. The income from the metal and precious stones used in jewellery making is linked to geopolitical conflicts or may have been used to finance extremist movements.

Read also: Smart Key: Key choices for a more responsible sourcing

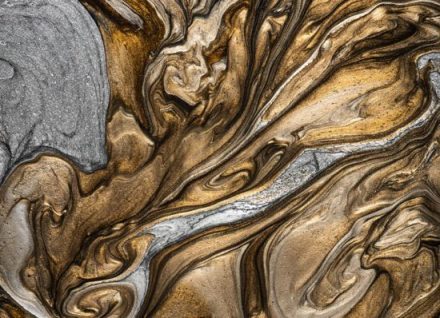

Alloys and galvanization, the challenge of alchemy

Metals undergo multiple stages in development. Before the final stage, they will be refined, where the metal is purified, then they will be combined with other metals to create an alloy in order to improve their properties, such as making them easier to pour, stronger or rust-resistant. In the fashion industry, stainless steel, zamak or brass are the most widely used.

Plating metals will then give them their final colour or will strengthen their resistance to wear, and means adding a fine layer of gold, silver, ruthenium or palladium.

The item will first of all be pre-treated to remove all oils and surface finishes, then the metal layer will be applied using an electrolytic, chemical or thermal process. It is then cleaned and rinsed to remove any excess product.

The wastewater from these galvanic processes contains solvents, oils and toxic heavy metals, making the post-production waste processing particularly complex. These operations must therefore be carefully regulated and monitored to protect the health of workers and the wastewater must be thoroughly filtered before being rejected.

The galvanic sludge formed during the wastewater processing is harmful to the environment and is one of the most toxic industrial waste products. Therefore it must be sent to special hazardous waste disposal centres.

In light of this rather sobering reality, what are the potential possibilities for eco-accessories?

Smart Key #1: Verify the mining conditions used for the metals

Metals are non-renewable resources and it is essential to monitor their geological availability, the mining and processing methods used and the security of the supply.

Fairtrade and Fairmined are the main certifications covering the environmental, social and economic aspects. They ensure that the ores do not come from conflict zones. On the environmental side, either chemical products are not used at all, or some lower-risk products are tolerated and carefully regulated. From the social perspective, these certifications guarantee safer working conditions, no child labour and better pay.

Another tool is the Transition Metal Tracker, created by the Business & Human Resource Centre. It identifies allegations of human rights abuses for six minerals, including zinc and copper, which are frequently found in fashion accessories.

Smart Key #2: Reduce the impact of finishes

Closed circuit systems where the waste water from electroplating is filtered and reused, offer an interesting alternative. They remain rare, for the time being, as they require a specific dedicated infrastructure and are expensive.

Galvanic sludge needs to be kept to a strict minimum, as it cannot be sent to the municipal waste processing centres. Its management is complicated, because special hazardous waste centres have to be specifically built and are also expensive.

Physical Vapour Deposition, PVD, is an alternative that reduces impacts. This technique produces a metal vapour, in a vacuum in conjunction with a harmless gas, and forms a highly adhesive coating. It produces less waste than classic electroplating techniques because the process requires no hazardous pre-treatment or cleaning products and uses a minimal quantity of water.

Another solution is to accept the natural effects of the metal and obtain subtly-aged surfaces by using only water and heat to create carefully calculated natural oxidisation.

Smart Key #3: Optimise dismantling and strengthen recycling systems.

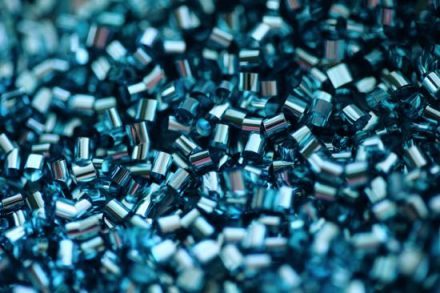

It should be remembered that metals have the advantage of being endlessly recyclable without any deterioration in quality, particularly when we are seeking a zero-waste approach. The Global Recycled Standard (GRS) and Recycled Content Certification (RCC) standards attest and measure the recycled content of a metallic product.

Recycling metals has a long tradition, being more efficient and profitable than continuing to mine and produce metals from scratch. For a long time, efforts were concentrated on metals like steel, copper and gold, as most of the products made with them were relatively simple.

With the complexification of products and the use of multi-materials, recycling becomes a more difficult task. Many metals are lost as a result of poor collection of products at their end-of-life, the low value of certain metals that means the necessary infrastructure is not profitable, unsuitable recycling practices and a lack of suitable technology.

Efforts must be made to consolidate recovery and processing sectors and to think about the end-of-life of a product from its very conception. If customers are encouraged to being their products back, in order to generate more substantial volumes of metal components for recycling, and design processes are optimised to ensure items can easily be dismantled, this will encourage an increase in the recycling of metallic items.

Sources :

- Controverses minières – Pour en finir avec certaines contrevérités sur la mine et les filières minérales- SystEx

- Prévention des risques professionnels du traitement de surface des métaux – Officiel Prévention santé et sécurité au travail

- Electroplating and PVD Finishing Technologies in the Fashion Industry: Perspectives and Scenarios – Romeo Bandinelli , Virginia Fani and Bianca Bindi

- Methods and solutions for galvanic waste water treatment – Nikolay Makisha, Maria Yunchina

- Metal Recycling, Opportunities, Limits, Infrastructure – United Nations Environment Programme

- Le recyclage des métaux – Eco info – CNRS

Learn more about sustainability with our Smart Keys series:

- The hidden face of cotton

- Cellulosic materials

- The mysteries of chemistry

- Biodegradability

- Traceability

- Alternative plant-based materials

- Polyester recycling

- The secrets of sports technical fabrics

- Eco-packaging