Recycled V2.0 by REO-ECO® The - Première Vision Paris

(Sponsored content)

Challenges & uncertainty do not stop the acceleration of REO-ECO recyclization for the textile industry. Instead, REO-ECO is starting a double recycle engine: One is bottle to textile recycling, the other is FDA food safety level bottle to bottle recycling.

This time, we are excited to share and focus on our new update for bottle to textile evolution.

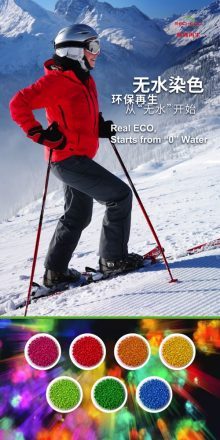

Real ECO, Starts from “0” Water.

Traditional recycling process consumed lots of water & energy, that is definitely not the future for recycling.

REO-ECO redesigned the whole water process and offer new solutions, from plastic bottle washing, using 100% recycled water and 30% solar energy, making the recycling process even greener with no fresh water is needed. Progress never stops. REO-ECO keeps working together with CSI, bringing the brilliant idea of making recycled colors from top selling list.

Brands can get a great recycled products from a simply spinning-knitting/weaving-cut & sew process, fabric dyeing is not needed any more. Brands designers would be able o have easier access to the sustainable materials by clicking their fingers to order their favorite recycled colors from the seasonal palette.

A new version of this book will be ready by end of 2022.

Micro Denier·High Performance

- REO-ECO Recycled Filament Yarns, from 2nd generation of recycling, we insist that recycling materials should ensure better experience from all aspects, compact but soft, lighter but stronger and better performance etc.

REO-ECO upgraded its purification process from bottle washing to chips screw extrusion to ensure 3 times finer of filament number than ever before. Higher Micro Level of Filament is just the beginning, REO-ECO will bring more consumer-friendly products with anti-microbial, wicking/quick dry and cooling/warming capabilities after 30X home laundry.

- REO-ECO recycled fabrics only apply PFAs and PFOs Free finishing for all kind of water repellent performance, giving a more safety and protective solution for our respected consumers especial for our lovely kids.

Lower Carbon, Higher Expectation

REO-ECO is recognized as Carbon Negative Manufacturer. To help all brands and retailers, to gain more beneath-iceberg values, not only for social responsibility but also for economical benefits to ensure real sustainability, REO-ECO is trying to set an example with The North Face.

Case 1: One piece Parka garment has REO 100gsm recycled poly (fabric consumption 1.5M/pcs)

|

Reduction item |

Saving Unit |

ICE in $ |

ETS in € | CCER in ¥ |

| 1.5M regular fabric carbon emission(kg) | 18.41 | |||

| 1.5M REO fabric carbon emission(kg) | 1.76 | |||

| Reduction (kg) |

16.64 |

1.5 | 0.5 | 0.4 |

For more info about REO-ECO updates, please email us to info@reo-eco.com for more details.

Visit our page on the Première Vision Marketplace ➔