Denim PV x Thegoodgoods: a how-to for eco-responsible jeans The - Denim Première Vision

Last year, Denim Première Vision partnered with the French media Thegoodgoods for an entire week of content about denim. The aim? To decipher all you need to know about eco-responsible denim: history, impacts, innovations, and of course, circular economy.

Discover the guide to eco-denim.

What is an eco-responsible denim and who is responsible for it?

48% [1] of the environmental impact of a pair of jeans is related to its use and its end of life, the responsibility is therefore shared: from the designer to the manufacture, through all the supply chain, from the owner to the actors of a garment end-of-life : reusing, reparing, recycling… The denim industry was one of the first stigmatized for its misfits on the planet. Thus the first to move towards a social and environmental transition. Among stakeholders of the change, the Smart Creation program of the group Première Vision was one of the first global solution offering sustainable sourcing alternatives and pushing innovation forward. But can we go further with eco-design?

Taking in account every steps in the life of a pair of jeans in order to reduce its carbon footprint without compromising style? This is the challenge raised by circularity: clean jeans in an infinite life cycle that doesn’t hurt the earth.

Now as a consumer more aware about the dark side of the industry, what labels and certifications to follow?

What if we could share the responsibility and get involved as brands are? In a circular economy, every one of us is an actor.

It seemed natural to address this guide to both brands and consumers. Lets be synergistic builders of a desirable future.

I Eco-design, the journey of a clean pair of jeans

Eco-design means both minimizing the impact of production and anticipate the end of a product life. Through this journey, every single choice (raw materials, dyes, assembling, finishing) taken by a brand may be rewarded by a well informed consumer. It’s a virtuous circle: the more we demand on brands, the more they make efforts. However, eco-design isn’t routine. Years of research and development have been carried out by the Ellen Mac Arthur Foundation: first through an inventory of the fashion industry proving the emergency to end a linear model (Make Fashion Circular [3]), second with the Program Re Design [4] to guide their transition. Today, the Foundation supports many international brands such as C&A, H&M, Gap or Guess.

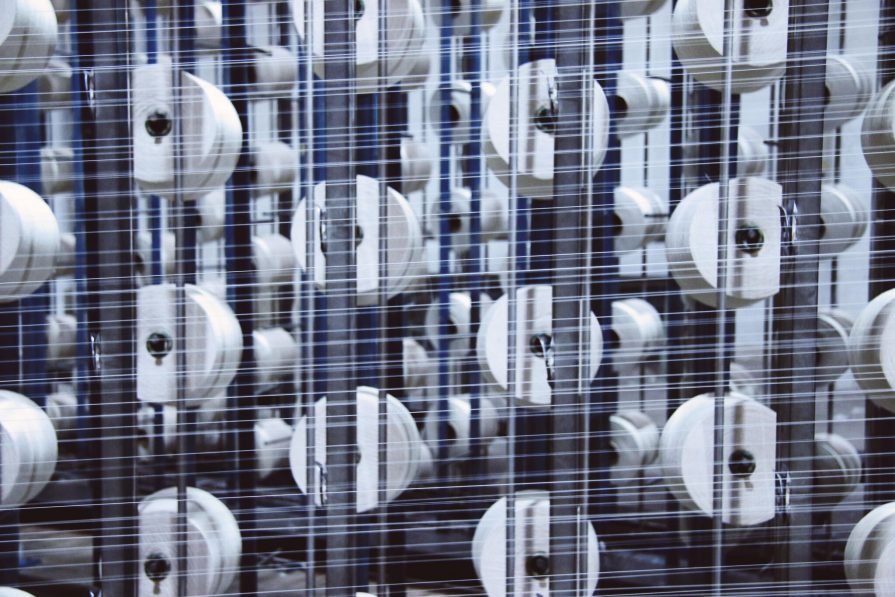

1) Sustainable and non-toxic materials [4, 5, 6, 7, 8, 9]

THE DIFFERENCE BETWEEN ORGANIC VS CONVENTIONAL COTTON

The raw material of denim is historically cotton. A switch to organic cotton is the first step towards responsible manufacturing. To explain the difference between the two, we have summarized the key points in an infographic. Non-organic cotton is also problematic during recycling. It makes the recyclable raw material more difficult to homogenize and therefore reassembly.

What are the alternatives?

- Recycled cotton: pre- and post-consumers, necessarily mixed with non-recycled cotton. 100% recycled is not (yet) resistant once spun because of the shortness of fibers.

- Natural materials: the use of cotton is historical… They are alternatives ! We can consider all types of cellulosic materials: hemp, linen (spoiler alert : a great project is coming at Dao Davy’s brand) lyocell , viscose. They have to be grown in organic or regenerative agriculture in order to be easily recyclable. A regenerative agricultural system is a system that preserves the integrity of a farm’s natural ecosystem, improving its health, biodiversity and resilience. The use of toxic chemicals should also be limited.

- Recycled polyester is an other option, recyclable infinitely

As a consumer

These fabrics can be certified.

- GOTS: Global Organic Textile Standard ensuring a traceable organic cotton and meeting social and environmental criteria.

- OCS: Organic Content Standard ensuring insuring a traceable organic cotton

- Bluesign, C2C Certified ™: these two labels ensure that the textile or finished garment is free from ZDHC (Zero Discharge Hazardous Chemicals) and can therefore be integrated into a circular chain.

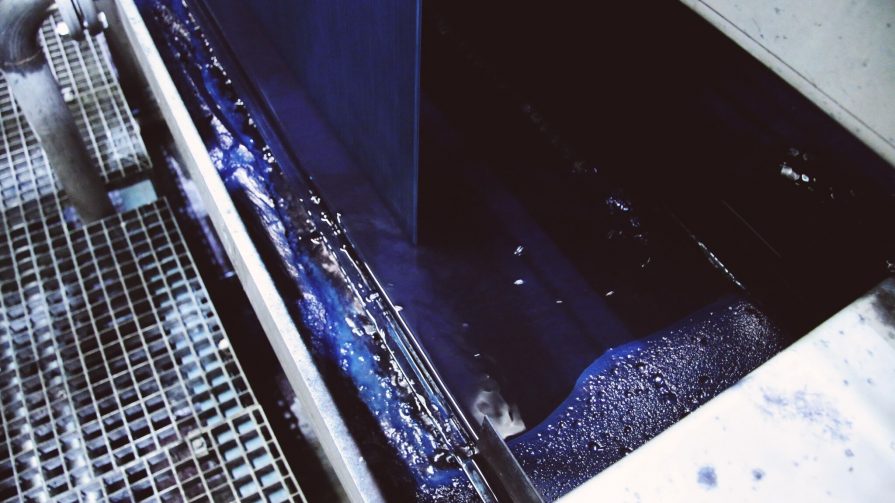

2) Cleaner dyeing

As a brand

Dyes require large amounts of rinsing water and chemicals for the prior cleaning of fibers and color fixation. Indigo, the favorite choice, can be synthetic or natural and renewable from the Indigofera Tintoria plant. However, its massive extraction affects its quality and reproducibility.

Today, Dyestar, Archroma or Berto offer a great selection of non-toxic indigo.

The company PG Denim has designed a dyeing system that reduces the amount of chemicals used by 40%, water by 50% and CO2 emissions by 60%. To date, traditional indigo is the least polluting way to dye denim. The use of recycled fibers sorted according to their colors also limits the impact, although the need for a re-dye remains systematic.

As a consumer

Dyes can be GOTS, Bluesign or C2C Certified ™ as well as the fabrics or the whole finished product.

The best way to reduce the impact of dyes is to optimize the maintenance of your pair of jeans and keep it as long as possible.

3) Non-hazardous finishing for both health and the environment

The bad habits

The “finishing” gives a worn look to a denim even new in opposition to “raw” ones. If the look looks damaged it also is a reality for the garment itself… Conventional finishing methods have long been extremely harmful to the environment and garment workers.

… Electroplating (an electric current finishing method) is deafening for employees and generates micro-waste with consequences that have not been evaluated yet.

… Stone polishing or stonenishing requires a large amount of stones, produces a residue agglomerating in the pockets, folds of the trousers and disappearing only after a number of washes.

… Potassium permanganate (PP) is a powerful oxidant whose contact with skin or eyes is highly irritating. This molecule accumulates in the ocean and is found in seafood and fishes[17].

… Sandblasting involves spraying sand at high pressure on the jeans. This method has proven to be very dangerous for workers, responsible for silicosis, lung fibrosis, severe respiratory failure of young jeans workers. It was denounced then gradually abandoned or saw its conditions improved (air filtration, physical protection of workers) by the majority of brands since 2010, under pressure of the Fair Trade Center reporting these consequences the same year [18].

Among these brands, there are giants like Acne or H&M. Things do change.

As a brand

Today, technology allows us to bleach a pair of jeans by minimizing clashes. Laser alternative is offered by Jeanologia. It’s an effective method carried out in a closed and ventilated machine by workers well equipped in safe conditions. The laser alters the surface of the wire by burning and revealing the white hues. The fabric scraps are collected and included in a recycling cycle. No more difficult handwork nor harmful chemicals ! Bleach can also appear with ozone converted to oxygen when released and apply to wet jeans secondarily rinsed. This method reduces energy consumption and water consumption and stone residue.

Today sandblasting must be forbidden. Checking on this remains the responsibility of brands along the entire supply chain. They must be able to provide transparency without blinking to gain consumer confidence.

However, the crush for faded jeans is quite recent and not enough to estimate the overall consequences of the bleach despite improvements in practices. Impairing the quality of jeans will always be less sustainable. So are trends leading to the constant need for change.

Ozone washing by @Jeanologia

On the consumer side

Determine the finishing method by looking at jeans is impossible. What is possible it is to favor companies choosing Jeanologia or a responsible fabrics suppliers. The best way to know is to ask the brand by an email, via Instagram, on WhatsApp, a chatbot … A no anwser is an invitation to pass…

Promote companies that communicate on the safety and healthy conditions for their garments workers: masks, ventilation, ear plugs, glasses and protective suits… The Fair Wear Foundation and Fair Trade labels are good indicators (not specific to denim nor exhaustive).

We recommend you to buy a raw denim to minimize your impact and enjoy of the clearing of your own patina!

4) Shorter supply chains

As both brand & consumer

Playing home! Because “de Nîmes” has (at least part of) its origins in France. We know the savoir-faire, we have the machines and expert garment workers. Why look further for a quality pair of jeans ?

It’s a fact, the impact of denim will always be proportional to the miles between the cotton growth and your dressing.

There are mills in Europe, Italy, France, Portugal and a little further in the North African textile basin. The finishing company Jeanologia is established in Spain. So produce and buy locally is possible and remains a choice.

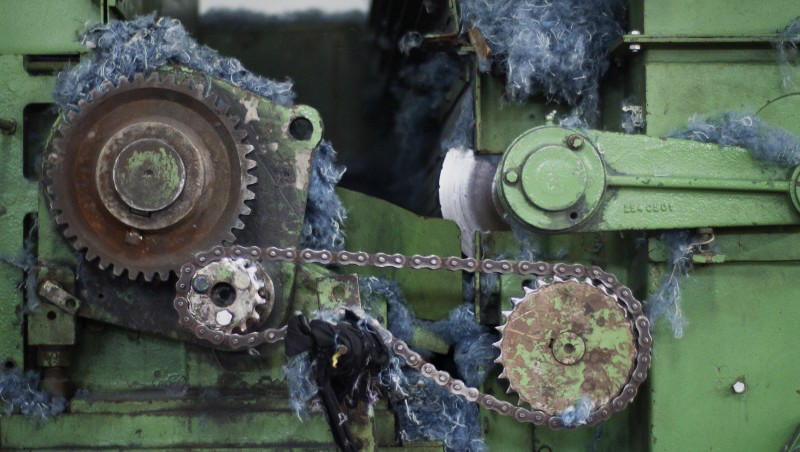

II Recyclability

1) Make denim circular [4,18]

As a brand

Hold on, there is something to do! The Ellen Mac Arthur Foundation wrote every single steps to follow in detail in The Jeans Redesign. The French brand 1083 takes the lead with Le Jean Infini. The potential of circularity is huge and by definition inexhaustible.

One of the pillars is eco-design: optimizing every step, material or stakeholder in the chain so that all of them help facilitate recyclability.

Recyclability: easier to do than to pronounce

So, what are you talking about? There are different degrees of recycling:

- we can upcyle garments

- unravel the yarn

- decompose the fibers … in polymers, in monomers … Then polymerize monomers again, secondarily aggregated in fibers giving yarns then a fabric. Now that you are in the loop, you understand that the more homogeneous the raw material, the easier recycling is. Ideally, only cellulosic fibers of the same nature (randomly, cotton), dyed with the same color with the same chemical. Long story short : it doesn’t exist. But we come closer ! The Redesign report commits brands to work with materials containing less than 2% of non-cellulosic fibers, possibly mixed. The 2% coming from plastics (elastane, polyester etc).

A homogeneous raw material

Recycling a pair of jeans isn’t just a fabrics issue. Any additional component must be considered: from the zip / buttons to the rivets (small metal nipples at the top of the pockets), to the labels. Each of its elements must be easily removed and repackaged or deleted. Furthermore, the sewing yarn and dyes must have the same certifications (Bluesign, C2C Certified ™). Now you really get why anticipating all these steps before production is crucial for a good recycling process. A reason why we believe in leasing and rental.

2) A proper recycling structure

As a brand

Effective traceability, leasing or renting are options to get your own “raw material” back to recycle, which Bert van Son of @MUDJEANS explains very well in our podcast. However, the volumes are often insufficient, which is why each brand must take the step of eco-design and all brands should follow one standard.

As a consumer

Sort properly!

III Sustainable garments

Until recently, sustainable fashion wasn’t desirable: the products, however ethical they were, suffered from an unfashionable reputation: no good fit, not comfortable enough. Ironically, buying a green pair of jeans left in the closet or getting tired of after 6 months is less eco-friendly than wearing a fast-fashion jeans for a lifetime ! Carbon footprint decreases over the years.

As a brand

According to the Ellen MacArthur Foundation, sustainability means:

- Physical durability: a good quality pairs of jeans supporting 30 washes or more without degrading the shape, outfit or color. Educate your customer, give them long-lasting advice, offer a repair corner or service, send repair-kit for free…

- Emotional durability: create a product whose desirability and style will withstand time

As a consumer

Make Fashion Circular – The Jean Redesign Project by @ELLEMACARTHURFOUNDATION

IV A traceable & transparent supply chain

The total traceability is complex. There is a disconnect between the different stakeholders of the supply chain. Tracing that chain and giving your customer an open access to it would help avoiding dramas such as the Rana Plaza, making every member of a brand responsible in front of the customer. Plus, full tracking would genuinely help facilitate recycling by garment identification.

They could be quickly sort by fabrics, dyes, certifications etc.

V An alternative to classic packaging

Recyclable craft paper?

… Plastic-like vegetable-based, compostable (Tipa Corp as an example)?

… Reusable packaging (Repack)?

… No packaging?

As a brand

Ask your customers about their packing/shipping methods preferences!

As a consumer

Ask the brands on any social networks or chatbots ! With a good picture telling that you are more interested in the garment than its box.

VI Production on demand

Here is a concrete example of a strong brand-consumer partnership. Pre-order is quite common now, customers know it supports a brand and leads to a meaningful purchase : the expectation of a desired item is the start of a sincere relationship, sustainable by all means !

It’s also better for factories no longer balancing between pre-sales rush and a lack of orders, stressful and unsustainable in one case like the other.

For a brand, this is a lifetime opportunity to create a strong relationship with customers and to be transparent by simply telling the true story and taking the readers to the next chapter.

And maybe in the future with #techforgood will do the fittings in Virtual Reality from our sofas, items will be modeled on our 3D-reconstructed bodies. A key for a slow fashion?

In the end, responsibility is less impressive when shared and well known. Whether you are a brand or a consumer, fashion also works in an ecosystem. No one is too small to have a big role in the clothing chain.

Circularity gives us the humility that fashion needs to move forward – as the saying goes – together, perhaps slower but certainly further!

REFERENCES

[1] ADEME – Carnet de vie d’un jean

[2] transparency-one.com/fr/how-ethical-denim-supply-chain/

[3] Make Fashion Circular – The Report – Elle Mc Arthur Foudation

[4] Re-Design Guideline Ellen Mc Arthur Foudation

[5] Communiqué de presse de la plateforme Textile Exchange – DERNIER RAPPORT sur la production mondiale de coton organique)

[6] ABout Organic Cotton

[7] Ademe

[8] Futura sciences : 9 Greenpeace, Dirty laundry: unravelling the corporate connections to toxic water pollution in China (2011), p.70

[10] KEMI, Chemicals in textiles: risks to human health and the environment (2014); Greenpeace, Eleven agship hazardous chemicals; Changing Markets Foundation, Dirty fashion: How pollution in the textiles supply chain is making viscose toxic (2017)

[11] See Rodale Institute, Nine ways you may not realise cotton is in your food

[12] D. Maxwell et al., State of the apparel sector report: Water, GLASA (2015), p.14; K.R. Dey et al., Impact of pesticide use on the health of farmers: a study in Barak valley, Assam (2013)

[13] jeanologia.com/

[14] Fashion victims : a report on sand blasted denim – Fair Trade Center

[15] levistrauss.com/2010/09/07/its-time-ban-sandblasting/

[16] http://www.thesupplychange.org/blog/waste-not-want-not-the-jean-pool

[17] See New Jersey Department of Health and Senior Services, Hazardous substances fact sheet

[18] Re-made en France par Thomas Huriez, Président Fondateur de 1083 – Éditions DUNOZ